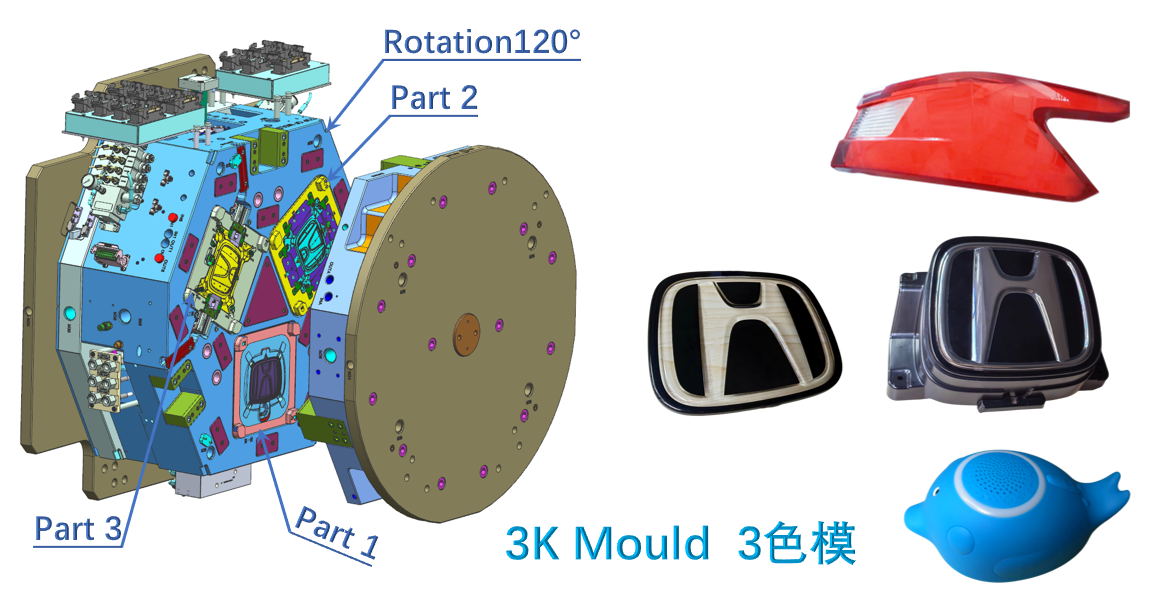

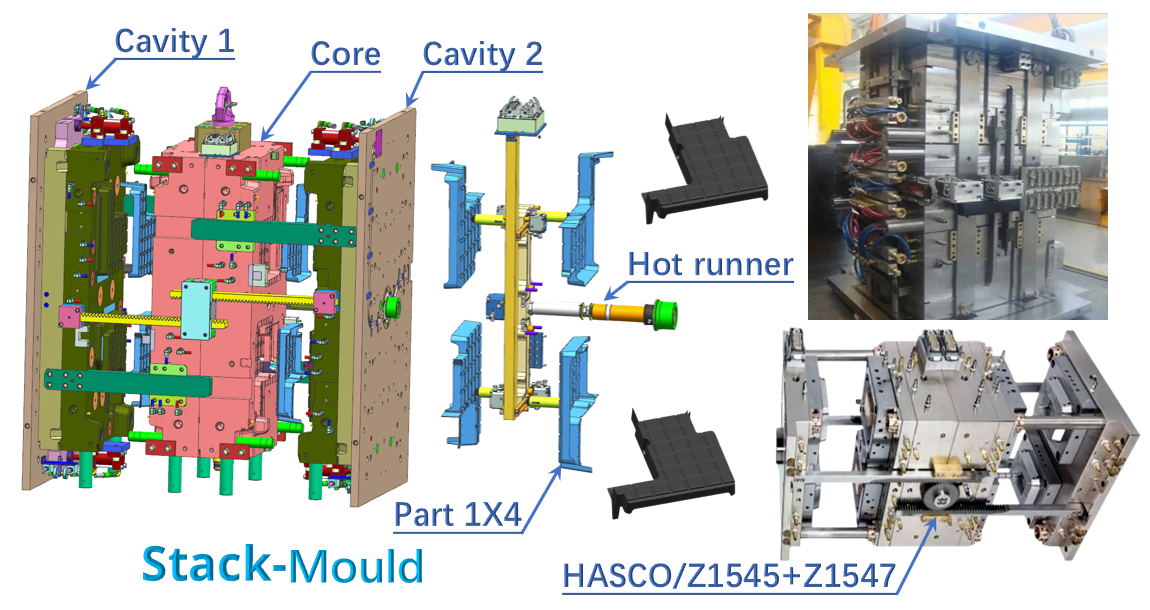

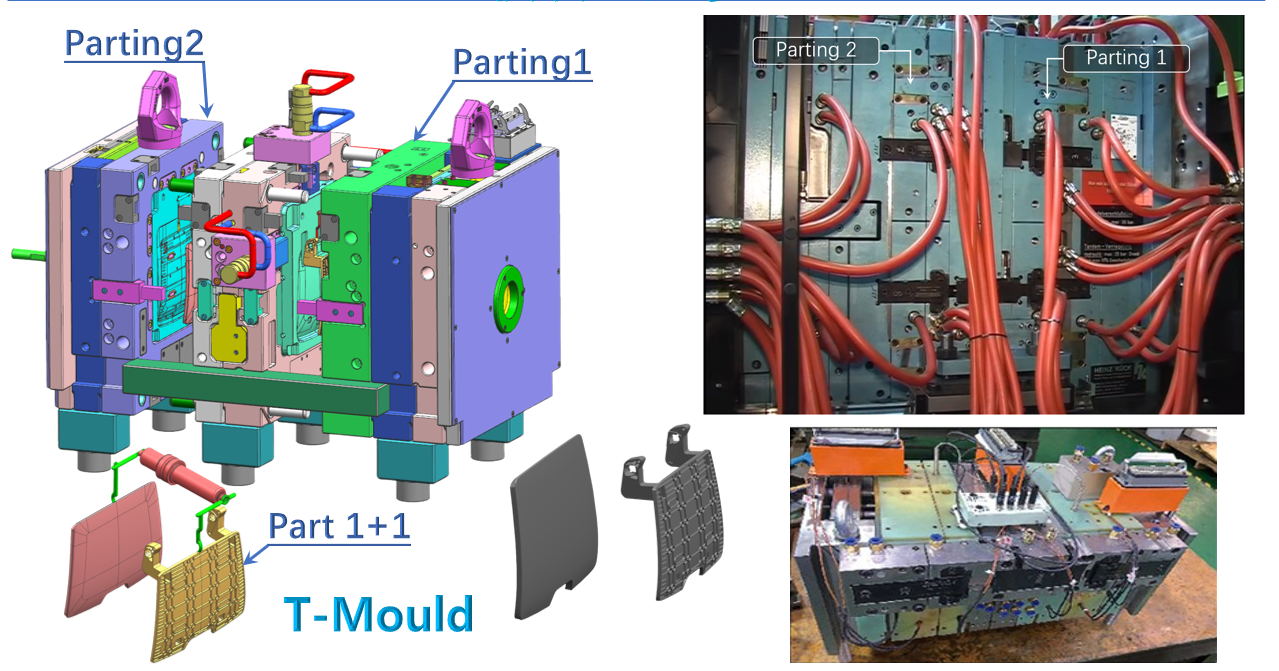

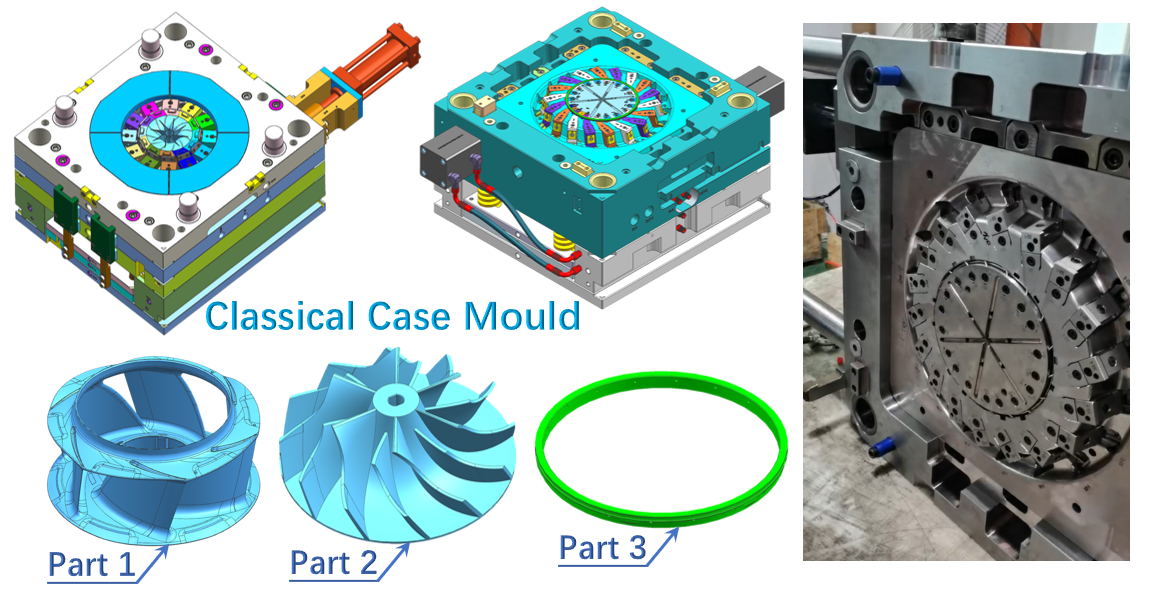

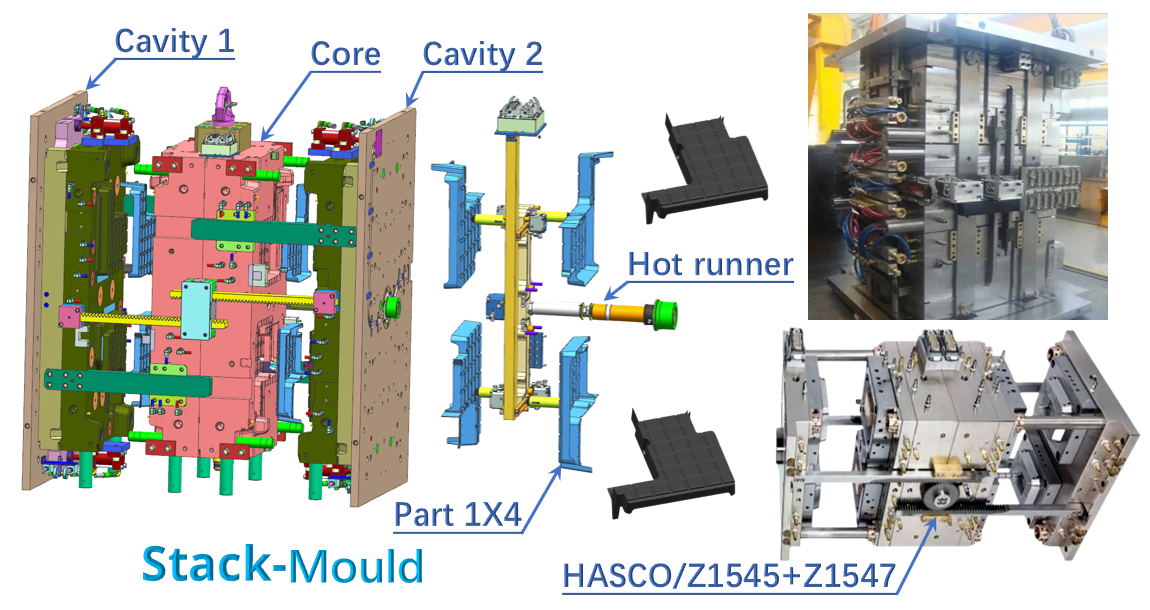

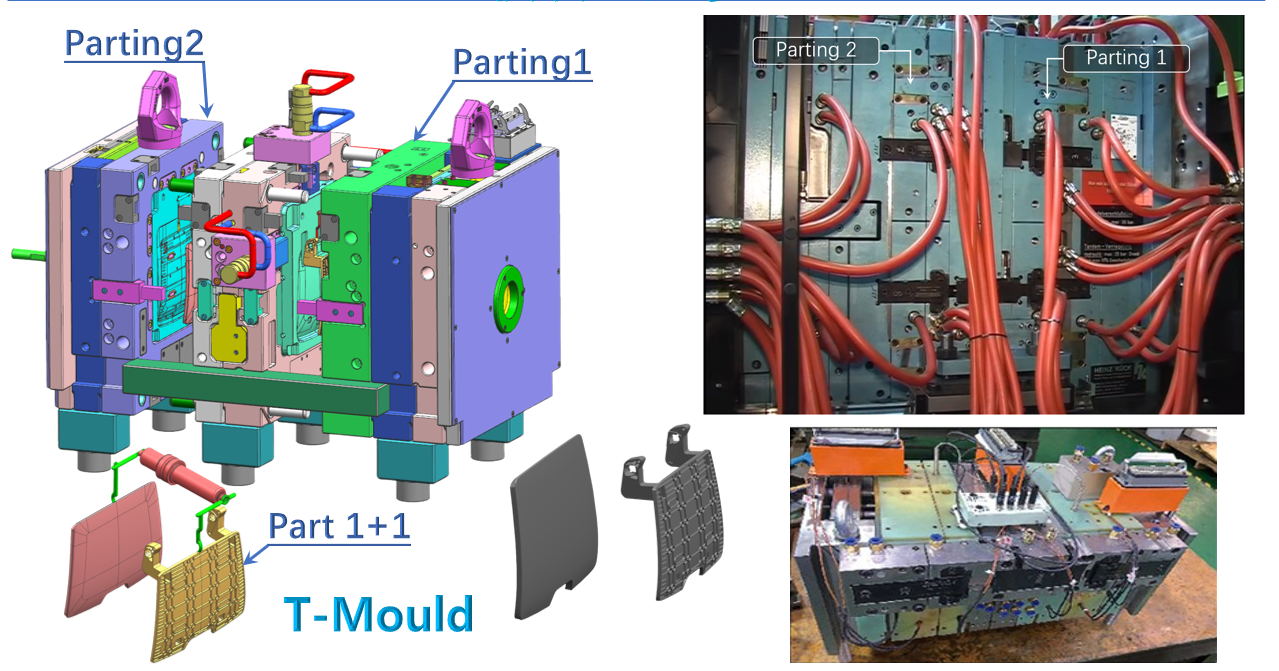

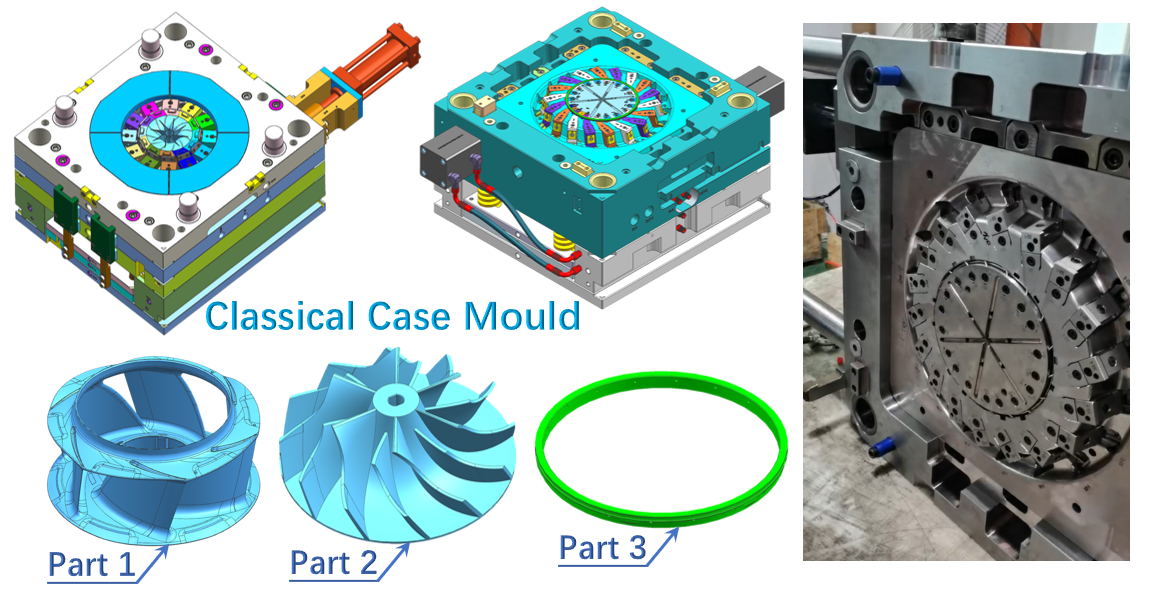

DIFFERENT 2K SOLUTIONS BY btd

DIFFERENT 2K SOLUTIONS BY btd